Hangzhou Ganjiang Industry Co. Ltd.

Contact: manager wu (Ms)

manager Sun (Mr)

Tel:0571-88635570

Fax:0571-88672050

Cel: 15967139371(Sun)

Email:2366835756@qq.com

Add:No. 12, ring Garden North Road, Zhongtai Industry Park, Yuhang District, Hangzhou

Deoxidizer - the importance of using safety packaging materials

The term "deoxidizer" is now becoming more and more familiar to consumers and more and more intersected with our healthy diet. As the name implies, As the name implies, the deoxidizer is to remove the oxygen in the packaging container,and then avoid being affected by oxygen., occur discoloration, moldy, oxidation and rancidity, insects etc.problems .

So do you know the process of its development and the evolution of the packaging material? Here is a brief description of this:

Deoxidizer, also known as "deacidification agent", was invented and popularized in the world by Japan. The most famous one is MITSUBISHI gas chemical company, Japan (MGC), which was started in 1918, and was founded in 1951. And our country began to develop deoxidizer in the end of 70s. It was first also due to the demand of military industry, and then gradually civil. Japan advocates low sugar, low salt, food eating habits, and most of these foods are difficult to preserve, so deoxidizer is widely used in the field. It is found that most of the deoxidizer inevitably need direct contact with food, and the moisture or grease in some foods will be adsorbed by deoxidizer, resulting in some hidden dangers and hazards:

①The powder particles in the deoxidizer leak out through the perforation of the material, which will pollute the food.

②Deoxidizer packaging material surface rust, grease or appearance of the watermark, influence the beauty of the product.

③Corrosion and destruction of deoxidizing agent packaging materials, there are stratification, easy stripping, fracture phenomenon, powder particles move out, resulting in heavy metal pollution of food.

④After the liquid water or oil seep into the inner layer of the packing material, the water film or oil film will be formed to wrap the powder, blocking the contact reaction between oxygen and iron powder. The oxygen absorption effect of deoxidizer is reduced or lost, and the oxygen atmosphere in food packaging can not be maintained.

⑤The packaging materials that are soaked by water or oil have become the medium of ion diffusion, causing heavy metals in the particles to migrate and contaminate the food.

So, how to improve and solve these problems? It is necessary to improve the packaging materials of deoxidizer so as to make them waterproof, anti oil and dust-proof, that is, the "Three Prevention" functions, so as to eliminate safety problems. The "Three Prevention" technology package was first applied in Japan, and then North America and Europe quickly recognized the safety of this material. At present, almost all the small food, cold fresh meat and other countries in Europe, America, Japan and other countries use the deoxidizer of "three defense" packaging materials. The use of "three defense" packages is very extensive, for example, the desiccant of food, and the strict requirements for packaging materials have been put forward.In 90s, the world-famous DuPont Co developed a packaging material with waterproof, oil and dust and antistatic function. It is called "Tyvek" paper. Because of its high security, Tyvek was highly recognized by the western countries and entered the Chinese market at the end of the 90s. Even now, the desiccant used in all kinds of products manufactured in China often uses "Tyvek" paper. Of course, the main reason is that foreign businessmen clearly specify the need to use "Tyvek" paper. In fact, it has also proved that the security of China's package has not reached the standard of the world for a long time, and it is not recognized!

When the application of deoxidizer was first popularized in China, the domestic material engineering was very weak, and packing with a kraft paper after a hole. Later, it gradually developed into a composite membrane, but the hole was still needed. In Europe, Japan and North America,The deoxidizer in the perforation process is not recognized because, from a microscopic point of view, the smaller pores also have the possibility of leaking. The standard of our country only stipulates that the aperture of direct perforation is less than 100um, which is far from the international standard.

In recent years, the state attaches great importance to the safety of food and medicine,and the enhancement of the people's health concept,the safety of deoxidizer is once again raised and heated.At the same time, China's packaging industry has also made a qualitative leap. At present, enterprises have developed the "Three Prevention" function, which can be directly contacted with food, and have been approved by the food industry in Europe, America and Japan.At the same time some domestic direct contact with the food industry more and more applications, such as baking industry, the industry standard of the moon cake has been clearly defined that the perforation process deoxidizer is not in contact with the moon cake, "Kangshifu" and other baking industry large enterprises is expressly deoxidizer packaging materials must be waterproof and oil proof performance. In the nuts, meat industry, has also begun to put forward strict safety requirements of deoxidizer packaging materials.

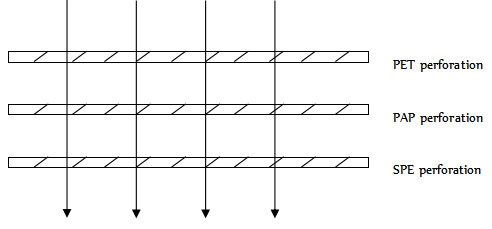

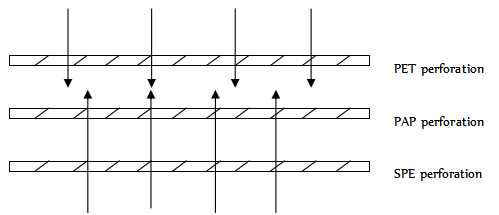

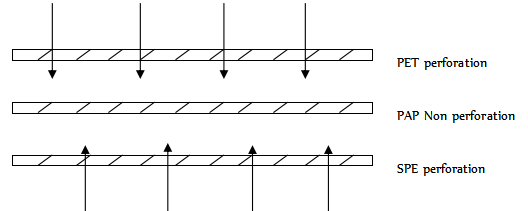

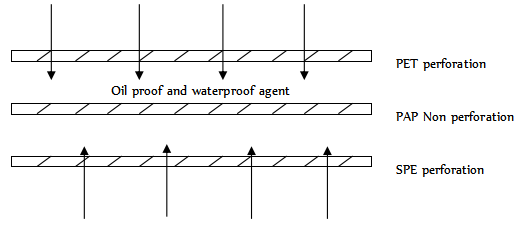

In the way of illustrations, the difference between the various materials is introduced. (the arrow shows the piercing needle, the transverse shadow line represents the structure decomposition of the package).

1)Schematic diagram of direct perforated material:

Because the three layers of the packaging material are directly penetrated, the deoxidizer powder will leak out from the hole. According to the strict regulation, the package material can not directly touch the food.

2)Schematic diagram of misplaced hole material:

The risk of powder leakage at the overlapped hole

The three - layer structure is also worn, but because of the misplaced hole material. It is perforated two times, and the two times needle type is different. It reduces the risk of powder leakage. But because of the overlapping hole phenomenon, there will still be the risk of powder leakage. Strictly speaking, the package material can not directly contact with food.

3)Sketch map of dust proof packing material:

The paper in the middle layer of the structure is not damaged, so there is no possibility of leakage. It can be directly contacted with food. Because of different processes, the thermal sealing strength of the dustproof material is much better than that of the dislocation hole and straight perforation.

4)Anti oil waterproof packaging material schematic:

On the basis of dustproof, through the anti oil and waterproof treatment, it can ensure that the direct contact with the food containing water and oil will not affect the performance of deoxidizer. Many foods contain water or grease. Although the content of oil in different foods is different, a small amount of oil will affect the performance of deoxidizer. In order to meet the function of direct contact with food, Japan and the United States used oil and water repellent materials in 1982.

China has a relatively late cognition of deoxidizer. The characteristic of Chinese enterprises is to consider the cost and not fully understand the food safety. Now many manufacturers who use deoxidizer don't know the purpose and effect of deoxidizer. They just follow suit. See the same industry in the use of deoxidizer, the product is also added to the deoxidizer, which is equivalent to giving consumers "stabilizer", which is actually their "tranquilizer". But the use of direct and misplaced holes not only does not give the food a shelf life, and the heavy metal in the deoxidizer iron powder will pollute the food.