Hangzhou Ganjiang Industry Co. Ltd.

Contact: manager wu (Ms)

manager Sun (Mr)

Tel:0571-88635570

Fax:0571-88672050

Cel: 15967139371(Sun)

Email:2366835756@qq.com

Add:No. 12, ring Garden North Road, Zhongtai Industry Park, Yuhang District, Hangzhou

Deoxidization and fresh-keeping of cooked aquatic products in Japan

1、Preface

Japan is facing the sea on all sides, so since ancient times, aquatic products have been used as an important source of animal protein. With the development of various processing technologies, aquatic products have become one of the ten daily diets of the Japanese. About 18% of the total aquatic products are processed in the Japanese new year. But aquatic products are easy to corrupt and oxidize, and they are difficult to keep fresh, and cooked products are no exception. But the advent of deoxidizer solves this problem.

2、The relationship between the decline of food quality and oxygen

There are many reasons for the decline in food quality, in which oxygen accounts for the vast majority. The oxygen that is indispensable to human beings is very bad for the preservation of food. The harm of oxygen to food can be divided into two kinds: direct and indirect.

Direct harm refers to the deterioration of food caused by oxidation. Pigment oxidation will make the food lose its original color. The oxidation of aromatic substances will make the food lose its fragrance. After the oxidation of vitamins and other nutrients, the food will lose its nutritional value. Aquatic products fat and more unsaturated fatty acids, nutritional value is very high, but very easy to oxidation, oxidation will be issued after rancid taste, easy to cause arteriosclerosis, myocardial infarction and carcinogenic fat peroxidation.

Indirect harm refers to some conditions that are unfavorable to food in an aerobic environment. Usually microbes and pests, like humans, rely on oxygen to maintain their lives. Rice cake, bread, cake, fish rolls are easy to moldy food, but also has carcinogenic mycotoxins, therefore, prevent the formation of toxic mold is an important issue in the work of food hygiene. Fish and fish roll fragile during storage and corrupt stink, this is mainly because the aquatic product contains a lot of moisture, protein, and carbohydrate, especially suitable for microbial bacteria, so that food spoilage, loss of food value.

In summary, the cause of the decline in food quality is oxidation and microorganism reproduction, all of the two are caused by the presence of oxygen. Therefore, the basic method of food preservation is to remove the oxygen in the food packaging, and eliminate the two factors that cause the quality of food. Because of deoxidizer effect which cause of the attention of the food industry , and it is rapidly expanded and applied in various fields.

Deoxidizer was introduced in 1977 as the latest and effective method for food preservation. The idea of removing oxygen from packaging is very early by chemical reaction. However, due to technical and cost reasons, commercial production is not yet formed. Until 1977, Japan's technical force succeeded in making deoxidizer the first commercialized production in the world.

In the production of deoxidizer in Japan, the oxygen indicator has been successfully developed to make the oxygen have or not have be visible.Oxygen indicator is a kind of tablet which changes repeatedly between the two colors of blue and red by oxygen. It makes the use of deoxidizer more convenient.

3、Effect of Deoxidizer on food industry

The listing of deoxidizer has made great changes in the food industry.

On the one hand, food is developing in the direction of raw food. Some called "raw " food, such as raw fish, raw noodles, mung bean vermicelli, cup Soybean Milk students have been listed, causing a "raw " tide. Then, the half - born sugar beans, semi - finished pastries, semi - finished fish and so on have also been successfully listed.

On the other hand, deoxidizer is also used to prevent the oxidation of VC and VE. VE is more easily oxidizing than fat. After the body's intake, it can be oxidized in place of fat, thus preventing the formation of peroxidation fat. But if VE has been oxidized before taking it, there is no effect. As VE can prevent fat oxidation, deoxidizer can prevent VE oxidation. Deoxidizer is also widely used in nuts, Italian sausages and salted fish containing a large number of VC and unsaturated fatty acids.

In addition to these two direct effects, Deoxidizer also brings great benefits to the food industry. The shelf life of food is greatly extended, thus greatly reducing the pressure of transportation. The longer the food is kept fresh, the value of its commodity can also be prolonged.

The birth of deoxidizer makes it possible for the preservation of aquatic products, and so is the cooked aquatic product.

This application with fish roll, to prove the preservation effect of deoxidizer.

In order to make the deoxidizer exert a perfect fresh-keeping effect, the following points should be paid attention to:

①Select the appropriate model number deoxidizer,

② Selection of film packing bags with good gas tightness,

③ Keep gas tightness.

Because the fish rolls, fish and other aquatic products, particularly susceptible to microbial invasion, therefore also must pay attention to:

①Keep clean and sanitary,

② Proper temperature control.

Grill fish roll deoxjdisation fresh-keeping test

Test method

The 150g fish roll and type F-X (moisture dependent) with deoxidizer sealed in the hermetically sealed film bag, stored at 5 degrees Celsius in the environment, regular measurement of concentration of oxygen and carbon dioxide in the bag, occurrence, smell and appearance observation of mold.

Test result

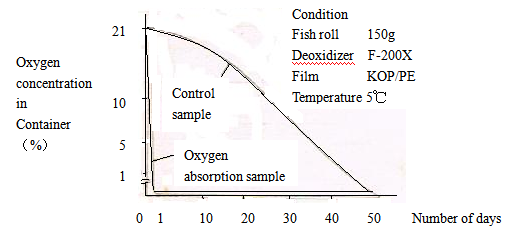

Figure 1 changes in oxygen concentration in the container with time

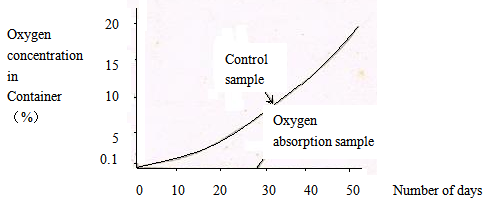

Figure 2 the change of carbon dioxide concentration in the container with time

Table 1 the occurrence of mould Temperature condition5℃

0 days | 4days | 11days | 18 days | 25 days | 36 days | 51 days | |

Oxygen absorption sample | — | — | — | — | — | — | — |

Control sample | — | — | — | + | ++ | +++ | +++ |

1)Oxygen concentration was reduced to less than 0.1% within 24 hours after oxygen absorption, and no moldy or carbon dioxide was produced in 50 days. The appearance is normal and the freshness is good. (Figure 1)

2)In the control sample, the concentration of carbon dioxide is increasing and the oxygen concentration slows down slowly. Since the eighteenth day, there have been the emergence of mold, and gradually increased, and start to stink, not edible. (Figure 2, table 1)