Hangzhou Ganjiang Industry Co. Ltd.

Contact: manager wu (Ms)

manager Sun (Mr)

Tel:0571-88635570

Fax:0571-88672050

Cel: 15967139371(Sun)

Email:2366835756@qq.com

Add:No. 12, ring Garden North Road, Zhongtai Industry Park, Yuhang District, Hangzhou

Deoxidization and fresh-keeping packaging of Japanese pastry food

1、 Preface

The application of deoxidizer in pastry food is much higher than that of other foods. From the sell of the deoxidizer, it was mainly used in pastries and later applied to food other than pastries. Although a variety of new applications are gradually produced, deoxidizer is still mainly used in pastries.

2、 Two application stages of deoxidizer

The deoxidization packaging technology of pastry food is divided into two stages. The first stage is to use only deoxidizer to solve the current problem of fresh-keeping. This stage of deoxidizer is widely used in small scale production of cakes, local cakes and special products in tourist attractions. Its main purpose is to prevent the return and compensation problems caused by the mildew. But this time did not give full play to the deoxidizer preservative effect.

The second stage is to put the deoxidizer into the leading position of the quality assurance technology and use it with other preservation technologies, so as to develop a new stage of all kinds of new fresh-keeping products. The specific performance is that a lot of half - life or nearly full - life and long - shelf life has appeared. It allows "a craze for raw food" and "health upsurge" as the slogan of low salt and low sugar existence and continuation.

These two stages are still mixed together to open the application market of deoxidizer, but with the progress of packaging technology and plant factory hygiene management , the latter occupies a more important position in the pastry industry.

3、 The mechanism of deoxidizer - we explain from two kinds of tidal currents

The most important role of deoxidizer in the food industry is the cause of "a craze for raw food" and "health upsurge". The two trends, as long as our standard of living is not decreasing rapidly, will not be instantaneous. In the future, it will also be used as a basic way of food preservation.

(1)A craze for raw food

The trend of raw food is not limited to the cake industry, but the development trend of the whole food industry. The term "Sheng", as the name suggests, is not heating, but also simplifying complex processes, increasing food moisture, making it soft, desalting flavor and reducing pigment addition. Such products are more acceptable to consumers, that is to say, food will develop towards manual and mild flavor, but this trend is not conducive to food preservation.

Deoxidizer is used to solve this problem of adverse preservation. It can be used in conjunction with health management technology, which can prevent spoilage caused by microorganism and discoloration and metamorphism caused by oxidation. Therefore, deoxidant has made an important contribution to fresh keeping of raw food.

(2)Health upsurge

The health heat of food is mainly reflected in the pursuit of natural food, low salt and low sugar food and vitamins. The abuse of food additives and the harmful effects of oil oxidation has been well known, and relevant laws and regulations have been set up by the state.

The principle of deoxidant is to reduce the oxygen concentration in closed containers to 0, so as to replace food additives to prevent oil oxidation, inhibit mold propagation, and maintain nutrients and food flavor. The fresh-keeping packaging of oxygen inhalant solves the problems of food additives, lipid peroxidation and the harm caused by mould.

4、 Conditions for the use of deoxidizer

Before the use of deoxidizer it is necessary to know the food of the perishability, circulation conditions, storage time, packing form, and oxygen content in the container. In the application of raw food, it is necessary to consider its water activity (Aw). Deoxidizer has an absolute inhibitory effect on aerobic microorganism at first, but can not completely inhibit yeast and anaerobic microorganism that can propagate in high moisture. However, compared with the ordinary packaging, the reproduction ability of these microbes decreased obviously when the oxygen inhalant was kept fresh and packed. Therefore, to strengthen the production and health management of the raw and cut cake factory will give full play to the effect of oxygen inhalant.

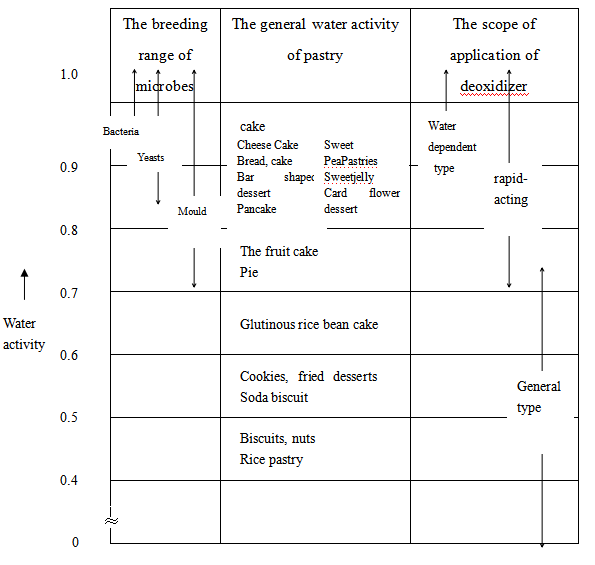

Figure -1 shows the relationship between water activity and microorganism in the general pastry food. Among them, the cheese cake and raw pastry without heating process and the use of quick acting deoxidizer can reduce the number of bacteria to the lowest in the early stage, so maintaining anaerobic state during the incubation period is the key.

Figure -1 water activity of pastry

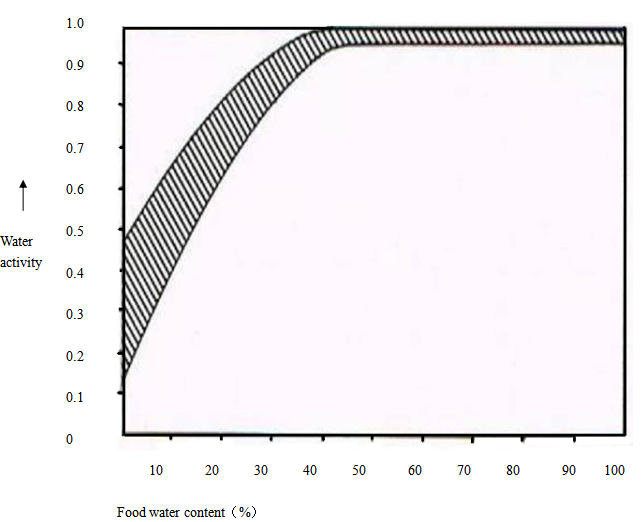

Figure -2 the relationship between water content (%) and water activity of food

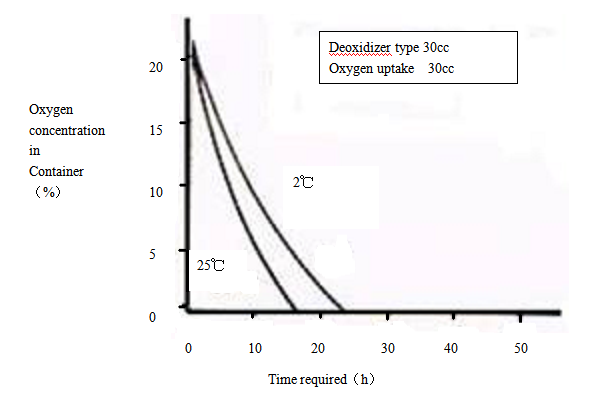

Usually, the oxygen uptake rate of deoxidizer decreases with the decrease of temperature. Generally speaking, if there is above freezing point, there is not much difference between oxygen uptake rate and room temperature. See figure -3, even in the freezing state, the oxygen absorption does not stop, at -20 C, deoxidizer can also reduce oxygen concentration to less than 0.1%. If the frozen deoxidizer is restored to normal temperature, its oxygen absorption speed will also be restored.

Figure -3 oxygen uptake rate of deoxidizer

5、 Packaging materials for deoxidizer

To make the deoxidizer a good effect of oxygen absorption, the packing container must have a certain air tightness. In general, the oxygen concentration is up to 0.4%, and the mildew can be reproduced. When oxygen concentration is below 0.1%, little oxygen does not cause food deterioration to fade. Therefore, the selection criterion for the barrier property of the package is that the oxygen concentration in the container can remain below 0.1% within the specified time.

In the short term the following 1 months, the oxygen permeation rate of 50~60cc/m2.atm.24h nylon / polyethylene composite film; for a period of 3~4 months, the oxygen permeation rate of 20cc/m2.atm.24h barrier better KOP/PE composite membrane; long time preservation can be made of metal cans and other packaging. It is reported that the oxygen concentration in the metal tank can reach to less than 10ppm. Oxygen indicators are usually used to simply determine whether a certain container is suitable for the packaging of oxygen inhalation agents.